The most important types of printed circuit boards

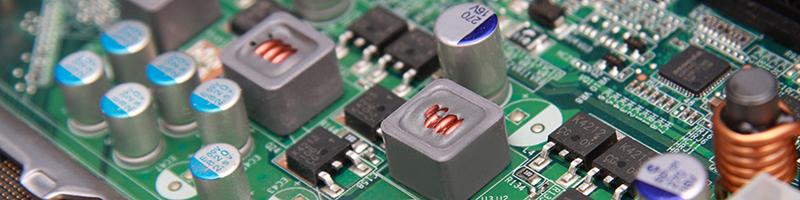

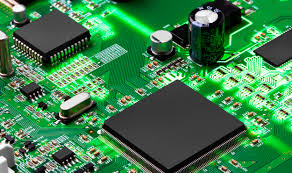

Rigid Printed Circuit Boards (PCBs): Rigid printed circuit boards (PCBs) are named because they are made of rigid, strong substrate materials. Fiberglass is the most commonly used material. Once a rigid printed circuit board has been manufactured, it may not be modified or replaced during the life of the device. The panels help to improve the service life of the components and are less prone to damage due to their strength. One good example of a rigid printed circuit board is a computer motherboard that distributes power while allowing communication between other parts of the computer, including the GPU, RAM, and processor.

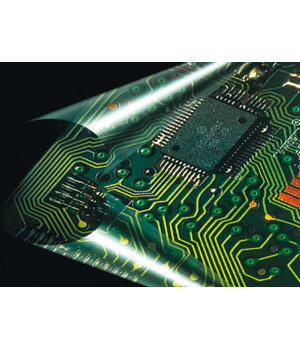

Flexible Printed Circuit Boards (PCBs): Flexible printed circuit boards offer more flexibility because they are made of materials that can move and bend. Like rigid printed circuit boards, flexible printed circuit boards come in single, double, or multilayer formats. Flexible panels are made of materials that are resistant to corrosion, moisture, oil, temperature and shock. Flexible boards are used in various fields such as telephones, laptops, cameras, light emitting diodes, LCD manufacturing and more.

Rigid-Flex Printed Circuit Boards (PCBs): Rigid-flex circuit boards combine both rigid and flexible board configurations into a single board. This gives the printed circuit board strength and flexibility. A simple and lightweight rigid-flexible scheme consists of a rigid plate attached to a flexible plate. The Rigid-flex board can be compact in design, making it an ideal choice for many applications, including mobile phones, digital cameras, pacemakers, and more.

Metal Core Printed Circuit Boards (PCBs): Metal core printed circuit boards, abbreviated as MCPCBs, are a great alternative to FR4 or CEM3 boards. Copper or aluminum cores are used for printed circuit boards. Aluminum base has good heat transfer and dissipation characteristics, and relatively expensive copper base has better properties than aluminum.