Let’s meet with printed circuit board … What is it?

A printed circuit board, also known as an insulating plate, is a plate on the surface of which there are electrically permeable tracks – printed wires consisting of a part of a metallized layer in the insulating part of the printed circuit board and contact areas for fixing electrical elements. Also metallized and non-metallized openings. Computer programs are used to design the contact drawing of the areas. The printed circuit board can be single-sided, double-sided, or multi-layered.

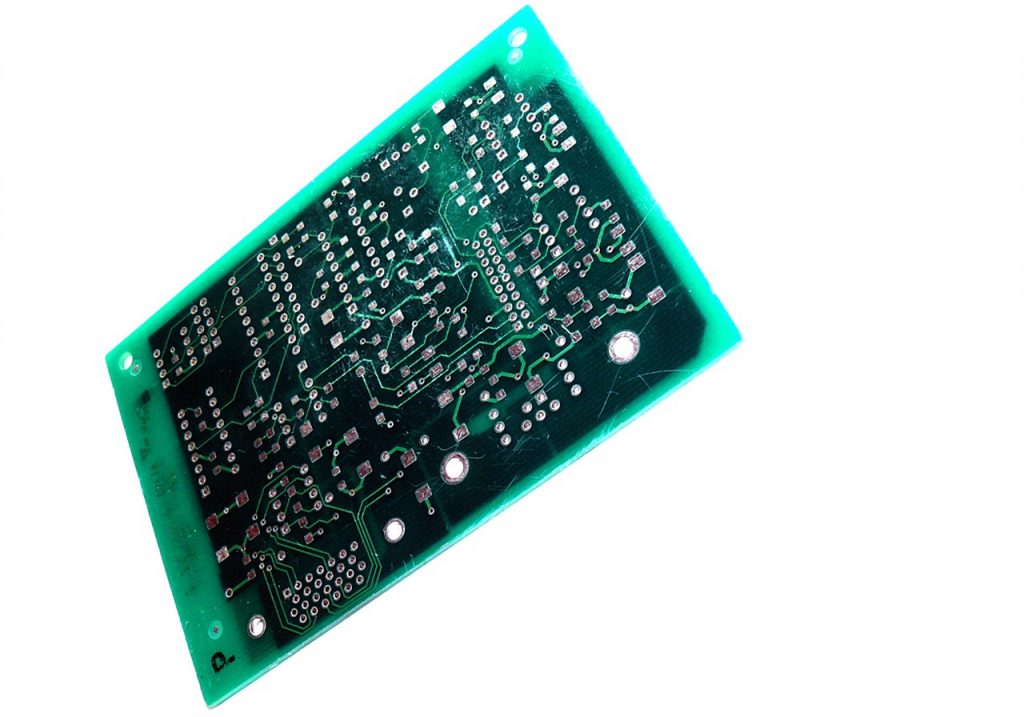

In the other hand, a printed circuit board is an electrical circuit whose components and conductors are in a mechanical structure. Conductivity properties are copper, heat sinks, or conductive planes. The mechanical construction is made of an insulating material laminated between layers of conductive materials. The overall construction is covered with an impermeable solder mask and silk graphic glass to help determine the position of the electronic components.

During production, the inner copper layers are engraved, leaving the intended traces of copper to join the circuit components. The engraved insulating material is then layered on the copper layers until the printing plate is finished. The components are added to the outer layers of the circuit board when all other layers are ready.

Also, before understanding what a printed circuit board is, it is worth figuring out what PCBs (organic compounds and pollutants) are. In short, towards a PCB, the goal of which was for one electrical compound to power many different devices – from smartphones to heart rate monitors was long and tedious for developers

Prior to printing the plates, electrical circuits were constructed by attaching individual wires to the components. The number of wires was so large that it was easy to confuse them with each other. The combination was difficult and the quality suffered. Production was slow, so components were soldered to the wired connections manually.

In the final version, the quality of the printed circuit board is tested. A robot-controlled contact or a contact field made specifically for the printed circuit board is used for this aspect.