Printed circuit board (PCB) materials

Printed circuit boards (PCBs) are usually a flat laminated composite made from non-conductive substrate materials with layers of copper circuitry buried internally or on the external surfaces.

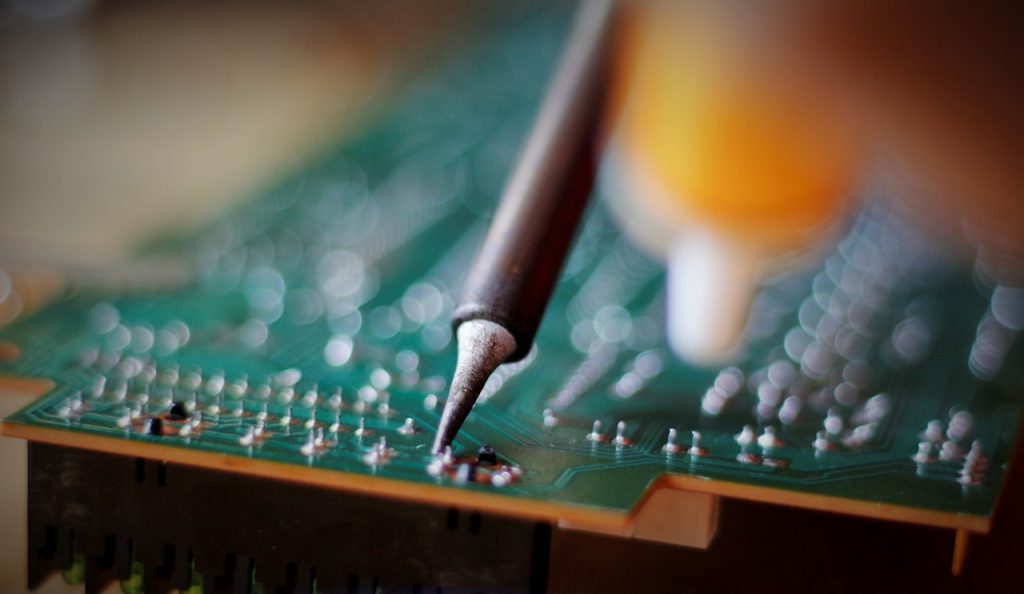

They can be as simple as one or two layers of copper, or in high density applications they can have fifty layers or more. The flat composite surface is ideal for supporting the components that are soldered and attached to the PCB, while the copper conductors connect the components to one another electronically.

The six basic components of a standard printed circuit board are:

- Prepreg

- Laminate

- Copper foil

- Solder mask

- Nomenclature

- Final finish

Prepreg is a thin glass fabric that is coated with resin and dried, in special machines called Prepreg treaters. The glass is the mechanical substrate that holds the resin in place. The resin – usually FR4 epoxy, polyimide, Teflon, and others – starts as a liquid that is coated onto the fabric. As the Prepreg moves through the treater, it enters an oven section, and begins to dry. Once it exits the treater, it is dry to the touch.

When Prepreg is exposed to higher temperatures, usually above 300º Fahrenheit, the resin begins to soften and melt. Once the resin in the Prepreg melts, it reaches a point (called thermosetting) where it then re-hardens to become rigid again and very, very strong. Despite that strength, Prepreg and laminate, tends to be very light. Prepreg sheets, or fiberglass, are used to manufacture many things – from boats, to golf clubs, aircraft, and wind turbine blades. But it is also critical in PCB manufacturing. Prepreg sheets are what we use to glue the PCB together, and they are also what is used to build the second component of a PCB – laminate.