Types of electronic boards

There are three types of electronic boards: printed circuit boards (PCBs), breadboards and striped electronic boards. Anyway, what is it?

Printed circuit boards (PCBs) are used to mechanically support and electrically connect electronic components using conductive tracks or signal tracks engraved from copper sheets laminated on an impermeable substrate, commonly used in the manufacture of manufacturing machines and computers. Printed circuit boards have copper tracks that connect the holes into which the components are placed. They are designed specifically for each circuit and greatly facilitate construction.

A breadboard is a rectangular plastic board with a bunch of small holes. These holes make it easy to insert electronic components for prototyping (i.e., developing and testing an early version). A breadboard is used to form temporary circuits for testing or testing an idea. Soldering is not required, making it easy to change connectors and replace components. The parts will not be damaged, so they can be reused later. Almost all Electronics projects have started “life” on a board breadboard to test that the circuit is working as intended.

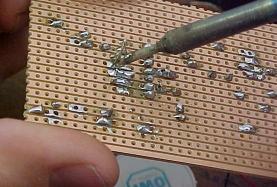

Stripboard electronics are one of the most commonly used types of prototype boards. These boards are designed to permanently mount disposable circuits, especially prototypes. The board is made of an insulating material, usually resin-bonded plastic or fiberglass. A prototype circuit can be built and tested in stages. The stripboards are used to form permanent soldered chains. This is ideal for small circuits with one or two ICs (chips), but with a large number of holes, the component is very easy to connect in the wrong place. For large, complex circuits, it is usually best to use a printed circuit board (PCB) if you can buy or manufacture it. The strip boards do not require special preparation, except for cutting to size. It can be cut with a younger hacksaw or simply locked along the holes by moving it to the edge of a bench or table and pushing hard, but be careful as this will require quite a bit of force and the edges will be rough. You may need to use a large pair of pliers to scrape off any toothed parts.