Dangers of electronic boards

The generation and management of electronic waste is one of the most important environmental issues of particular importance in recent decades. Electronic waste is generated at the very beginning of the production of each product with unprocessed raw materials and is subsequently generated at each stage of this process until the unprocessed raw material becomes a consumer good. The electronics we buy become waste after a while.

Electronics don’t last forever, and if they last longer than expected, they end up being replaced by technological advances or aging. Every year, 300 million computers and a billion mobile phones are produced worldwide, each with an average life cycle of 3 to 5 years. The amount of this waste is growing rapidly every year and increases by about 5%. So, all these billions of devices have to be removed somewhere every year.

Electronic waste can have a negative impact on the environment and human health if not properly managed. Disposal of this waste in landfills leads to contamination of soil, surface water and groundwater. Improper management of electronic waste poses a risk to human health and the environment, and increases the likelihood of toxic substances entering the human body and environmental components. Nevertheless, the disposal of this electronic waste in landfills is still the cheapest way to dispose of waste.

Disposing of electronic waste is highly irrational because new materials are much more expensive to produce and extract than to extract from waste. Studies show that extracting metals from waste can save energy: aluminum – 95%, copper – 85%, lead – 65%, zinc – 60%.

Extracting metals from unused electronic equipment is very important, because according to current data, the use of metals in industry is growing significantly, and in the long run we may run out of them. For example, platinum (Pt), lead (Pb) and rhodium (Rh) extracted from ores are used in more than 50% of the production of automotive catalysts alone.

Electronic devices can be recycled by manual disassembly as well as mechanical, chemical and thermal methods. The aim of these technologies is to rationally combine economic and environmental aspects.

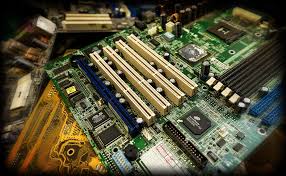

Electronic boards are a piece of equipment that supports electrical connections between individual components. They are found in many products: mobile phones, computers, televisions, printers. The panels consist of many components. The recycling of obsolete electronic boards is a very complicated process, as they consist of many complex components – sets of hazardous and non-hazardous materials. Average composition of electronic boards: 40% by weight of metals, 30% of plastics and 30% of ceramics. Real electric or composition: 40% by weight of metals, 30% of plastics and 30% of ceramics.

Genuine electrical or electronic components make up only 3% of the product weight.

The following metals are found on electronic boards: copper, iron, aluminium, tin, as well as rare metals such as tantalum, gallium, etc., and precious metals such as gold, silver and palladium. Copper makes up about 10-20%, lead 1-5%, and nickel 1-3% of the weight of the electronic board. Precious metals – gold, silver, platinum and palladium – account for 0.3–0.4%. Due to the uniqueness of these electronic parts, conventional electronic recycling technologies do not give the desired result.